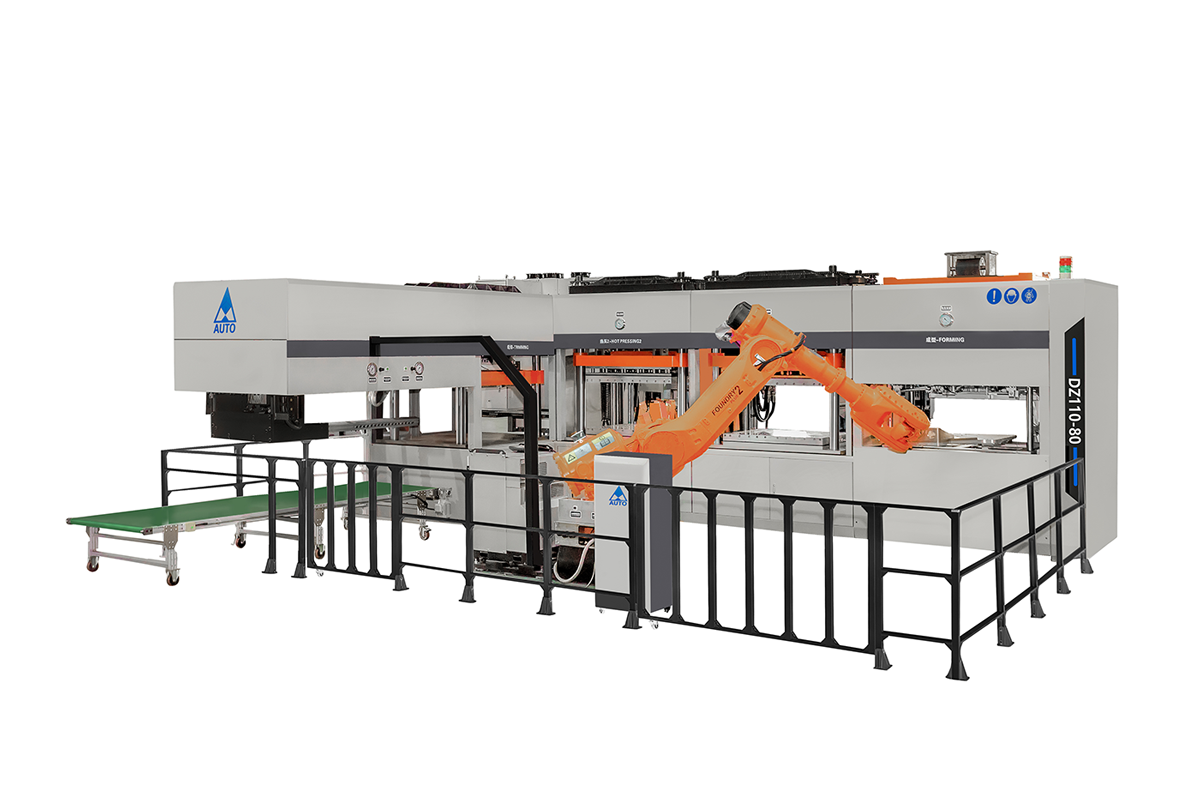

Nhanhatu Axis Robot

Pulp Molding Machine

Biodegradable Tableware Machine

Inoraswa Bagasse Shuwa Fiber Pepa Pulp Tableware Machine

Pepa Pulp Kudya Bhokisi Kugadzira Machine

Yakazara Otomatiki Pepa Pulp Plate Kugadzira Machine

| Model | 6-axis robhoti |

| Kuumba mhando | Reciprocating kuumba |

| Kuumba saizi | 1100mm x 800mm |

| Max. Kuumba kudzika | 100mm |

| Kupisa mhando | (192kw) Magetsi |

| Max. Press pressure | 60 tani |

| Max. trimming pressure | 50 tani |

| Simba rekushandisa | 65-80kwh Zvichienderana nechigadzirwa chimiro |

| Kushandiswa kwemhepo | 0.5m³/min |

| Vacuum kushandiswa | 8-12m³/min |

| Capacity | 800-1400kg / zuva Zvinoenderana nekugadzirwa kwechigadzirwa |

| Kurema | ≈29ton |

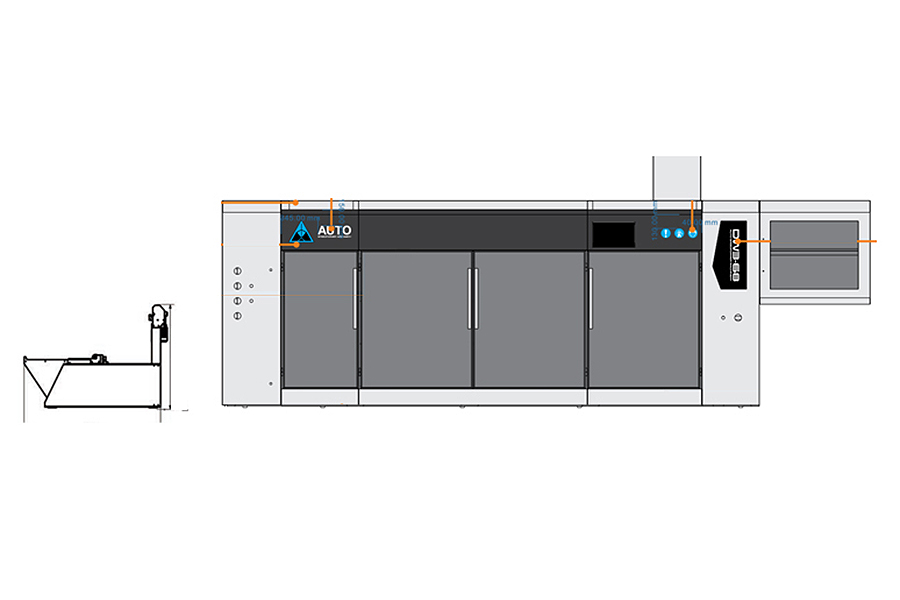

| Machine dimension | 7.5m X 5.3m X 2.9m |

| Rated power | 251kw |

| Kukurumidza kugadzira | 2.7cycle/min |

♦ Disposable Tableware

♦ Mapepa Mapepa Nemabhodhoro

♦ Fast Food Take-away Bhokisi uye Lid

♦ Yakagadzirira Kudya Packaging Trays

♦ Supermarket Fresh Trays

♦ Branded Food Packaging

♦ Cup uye Lid

♦ Cup Holder uye Vatakuri

1) Yakangwara HMI control system, yakazara yakavharwa-loop kugadzirwa.

2) Yakakwana yekudzivirira kukanganisa basa: otomatiki kumbomira uye alarm kana imwe link yatadza.

3) Imwe-kiyi yekumhanyisa kugadzira maitiro.

4) Servo kutonga kwemuchina wese, yakakwira kugadzirwa kwesimba, yakaderera mashandisiro esimba, kuchengetedza kwesimba kweanopfuura makumi mashanu muzana uye kuwedzera huwandu hunodarika makumi matanhatu%.

5) B&R tembiricha yekudzora: kudzora nzvimbo, kuchengetedza simba, kupisa nzvimbo munzvimbo gumi neshanu kumusoro uye pasi, isa tembiricha yakasiyana zvichienderana nekudzika kwezvigadzirwa.

6) Muchina wese wakashongedzerwa nekuyeuka uye kuchengetedza data mabasa (formula chengetedzo uye yakananga kuendesa kune mold shanduko). Inogona kugoneswa nekiyi imwe uye yakananga kupinda mukugadzira.

7)Otomatiki lubrication system (otomatiki nguva yekuisa mafuta)

8) Ductile iron castings yepuratifomu yekushanda (simba rakakwirira uye kumwe kuoma)

9) Muchina wese hauna mvura uye unopokana nekuora

10) Yakasarudzika uye yakasarudzika inopisa yekutsikirira, hombe yekuburitsa mutsi epombi pombi system, yakaganhurwa tembiricha yekudzora kuti ive nechokwadi chekudziya kwechikamu chimwe nechimwe mumakomba.

11) Yakanakira mold kurodha uye kuburitsa basa, yakasarudzika mold yekumisikidza mudziyo, inovandudza zvakanyanya kugona kwekurodha uye kuburitsa mold.

.

13) Iyo inosimudzira inorembera manipulator inopedzisa kudzokorodza otomatiki kwezvinhu zvemupendero uye kuverengera kuverengera kwezvigadzirwa.